Loading... Please wait...

Loading... Please wait...Injection Molding Explained - How PP and PS Jars and Containers are Manufactured - How Parkway Plastics Manufacture Plastic Jars

Posted by Parkway Plastics Team Member on 10-11-2016

The injection molding process was first established in the 1930s. Injection molding is today one of the best processes for producing solid and durable plastic jars. Polypropylene (PP) is a common thermoplastic material used in injection molding. Another thermoplastic that is commonly used is Polystyrene. These thermoplastics are often used across the world for the manufacturing of injection molded parts. Parkway Plastics manufactures plastic jars in Polypropylene and Polystyrene in Parkway’s injection molding machines. Let's learn all we need to know about injection molding:

Injection molding machines can produce plastic parts for rigid walls such as plastic jars and plastic containers. There is minimal waste in injection molding as the scrap can be recycled again. Being an injection molding manufacturer of plastic jars, we do all we can to reduce waste in and throughout the manufacturing process.

How does Injection Molding Work?

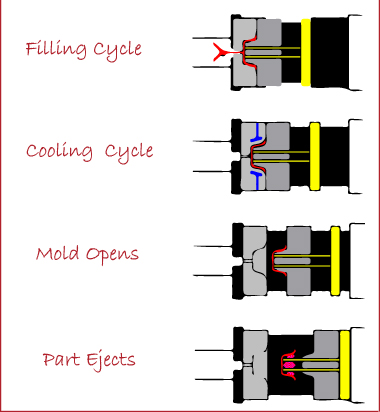

Injection molding manufacturers produces high numbers of

plastic parts with high quality, very fast. Material is fed into a heated

barrel where it is also melted. When smooth enough, the material is injected

through a nozzle under pressure (filling cycle) to fill a mold cavity and then cools off (cooling cycle).

Thereafter, the mold opens and the part ejects.

Injection Molding Explained:

Characteristics for Injection Molding:

- Tool = Mold

- Plastic material is melted and injected into the mold, after cooling the component is ejected from the mold

- Process = Cyclic (each time mold is filled, cooled and component is ejected)

Injection Molded Plastic Parts

From car bumpers and tiny automotive parts to plastic jars and packaging – the injection molding technique is used for production of tiny necessary parts to larger parts throughout different industries.

Here are a few examples:

- Frisbee (solid part)

- Hair combs

- Bottle Caps

- Body Panels for Cars

- Plastic Jars

- Plastic Containers

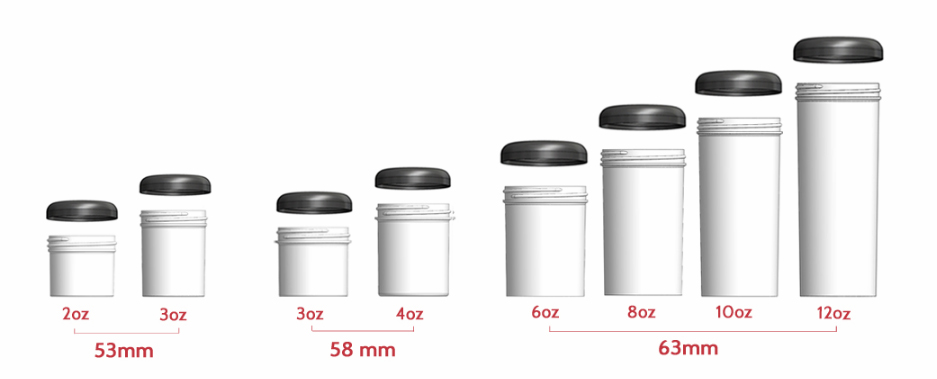

Parkway Plastics is a plastic jar manufacturer based in Piscataway, New Jersey. At our East Coast plant, our injection molding machines manufactures different plastic jars and caps, ranging from 33 mm to 120 mm in diameter. Parkway Plastics stock jars and caps at their manufacturing warehouse as they run different parts through their injection molding machines continuously.

With short lead times, and the ability for customers to personalize their jars and caps - Parkway is one of the premier manufacturers of Plastic Jars and Caps in the country. Learn more about Parkway here.

NEXT READ:> Blow Molding Explained - How PET Jars and Containers are Manufactured!

Ref.

https://www.xcentricmold.com/about-injection-moldi...

https://www.creativemechanisms.com/blog/five-thing...

Recent Posts

- » Unlocking the Potential of Plastic Jars: Your Ultimate Storage Solution

- » The Ultimate Guide to Choosing the Perfect Plastic Jars for Your Needs

- » Parkway Plastics Wide Mouth, Round Body: Shop the Perfect Plastic Jar Here!

- » The Versatility and Innovation of Plastic Jars and Bottles

- » High-Quality Plastic Jars and Bottles for Every Need