Loading... Please wait...

Loading... Please wait...Blog - JARS

Blow Molding Explained - How PET Jars and Containers are Manufactured!

Posted by Linda Thell on 08-07-2025

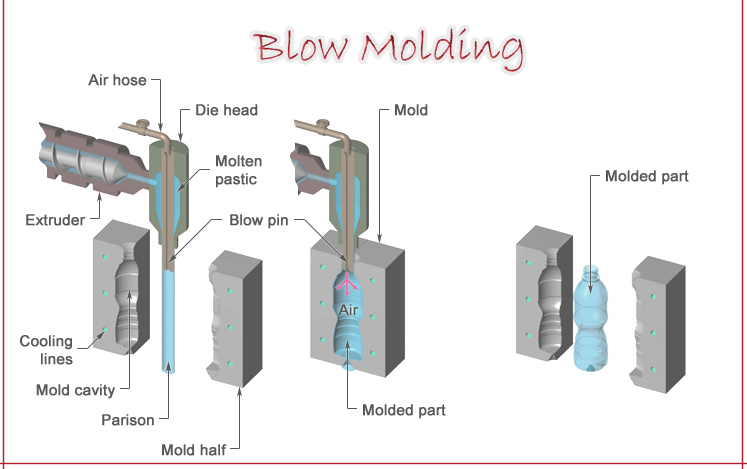

Blow molding is a manufacturing process that allows hollow plastic parts to be formed. Air pressure is used to inflate soft plastic into a mold cavity. The technology of blow molding comes from the glass industry; and plastics compete in the disposable and recyclable bottle market. The three main types of blow molding are: extrusion blow molding, injection blow molding, and injection stretch blow molding. Blow molding can make containers and jars such as blow-molded PET or PETE Jars and Containers for Packaging.

According to Customparts.net, parts made from blow molding are plastic, hollow, and thin-walled, such as bottles and containers that are available in a variety of shapes and sizes.

Blow molding is an important industrial process for making one-piece hollow plastic parts with thin walls, like plastic soda bottles, or water cans, or shampoo bottles. We are hence exposed to blow molded products throughout our daily lives.

Blow molded product examples:

- Bottles

- Shampoo bottles

- Watering cans

- Coolers

- Toys

- Containers

- Trays

How does the blow molding process work?

Blow molding is a two part plastic manufacturing process.

The first part of this plastic manufacturing technique starts by creating starting tubes of molten plastic, called Parisons. These are needed as the base for the extrusion blow molding process, regardless of the type of plastic bottle, container or part that is being created. After the Parisons are fabricated and ready to be blow-molded, the second part of the process can begin. If however, we are talking about injection blow molding or injection stretch blow molding, the first step in that process is called making a Preform, and not a Parison.

The second part of the manufacturing process is the air inflating of the tube or preform to the desired shape.

Forming it into the final product shape is done by either of three processes:

1 Extrusion blow molding,

2. Injection blow molding, or,

3. Injection stretch blow molding.

The PETE jars offered by Parkway are blow molded. Learn more about Parkway’s selection of PET jars, container and packaging here.

PET and PETE = Same thing. Polyethylene Terephthalate - Very usual thermoplastic that is widely blow-molded across the world into shapes and forms of jars, bottles, containers and packaging.

Side note: That peanut butter jar in your fridge, that's PET (PETE) for you.

1. Extrusion Blow Molding (EBM)

- 1. Parison Extrusion

- 2. Blowing

- 3. Cooling

- 4. Ejection

The extrusion blow molding process starts with a parison, as explained above. Hot air is blown into the hollow tube (the parison), which inflates the tube into a hollow part, depending on the shape of the mold cavity. Extrusion blow molding parts can include plastic bottles, containers or jars. After the plastic has cooled off, the mold opens and the blow molded part is ejected and replaced by a new parison to repeat the process.

Tool: Die

2. Injection Blow Molding (IBM)

- 1. Injection

- 2. Blowing

- 3. Ejection

The process starts by injection molding the polymer into a heated cavity, onto a core pin.

The cavity mold forms the outer shape of the part and is based off a core rod which shapes the inside of the preform. The preform is shaped as a jar-or-bottle-Neck with a large amount of polymer attached to it. This polymer will eventually form the body of the jar. After the Preform mold opens, the core rod brings the part to the blow station. The core rod in which the part is attached to, opens up at its end and compress air into the preform. At this final station, the plastic part gets blown, cooled, and then ejected.

This manufacturing method is used for very small containers, including pharmaceuticals and hospitality samples. Milacron, an industrial machine brand with injection molding machines widely used by Parkway Plastics, is also a manufacturer of Injection Blow Molding Machines. The injection blow molding technique is used for the production of hollow objects in large quantities. This method is however, the least common of the three different blow molding techniques among manufacturers today.

Tool: Mold

The difference between EBM and IBM:

The main difference between extrusion blow molding and injection blow molding is that extrusion involves the plastic to get squeezed through a mold, called a die (in “blow molding language”). Think of it like extruding pasta dough through a machine, where you can adjust the thickness, length and shape of the pasta. You don’t place a mold onto the pasta; you push the pasta through the mold.

The words that set “injection blow molding” and “extrusion blow molding” apart are the words “through a die”, and “into a mold”.

Let me explain: Extrusion blow molding squeezes the plastic through a die to make a blow molded part; whereas, Injection blow molding pushes the plastic into a mold, then ejecting the part and inflates it with air once cooled off.

The last blow molding technique that I intend to explain is the Injection stretch blow molding method.

This blow molding technique is widely used with PET material in the manufacturing process of containers and bottles:

3. Injection Stretch Blow Molding

- 1. Injection

- 2. Stretching

- 3. Blowing

- 4. Discharge

Similar to the injection blow molding process, molten polymer flows into the injection cavity on a hot runner block in order to make the Preform. The core pin produces the inner diameter just like explained for the injection blow molding process, the core pin creating the inside, whereas, the injection cavity shapes the outside of the preform. After the injection molding, the part is held in its neck and rotated 90 degrees. Once in the right temperature, the preform gets stretched and air infused (blown) into its finished shape. When the preform is in its Blow-mold area, the molds close and a stretch-rod will stretch the part using two levels of air pressure. After its cooled off, it will get discharged.

Products that are typically produced using this method includes but is not limited to: Carbonated and soft drink bottles, Cooking oil containers, chemical containers, Health and oral hygiene products, and Bathroom and personal care products.

Ref.

https://www.sinotech.com/resources/tutorials/blow-...

http://www.custompartnet.com/wu/blow-molding

Stay Calm, Parkway’s Thick Wall Jars are Available in 28 different sizes! | Variety of Thick Wall Jars Online Now!

Thick Wall Jars in 28 different sizes... These single wall jars are thicker but are they better? Whether you vote for Parkway Plastics to be your Best Plastic Jar Manufacturer or not, there's no doubt that Thick Wall Plastic Jars from Parkway can be Perfect for your Product Packaging this Holiday Season! Thick Wall Jars have a [...]

Plastic Jars for Contract Filling | Contract Fillers Need Plastic Jars from Plastic Jar Manufacturers | Jars for Filling Equipment Can be Purchased in Bulk Online at Parkway jars.com

Contract Fillers Need Plastic Jars Contract Fillers and Co-Packers Specialize in Packing Products in Empty Plastic Jars, Tubes, Containers, Pots and Bottles. Parkway Plastics Inc. works with Contract Fillers and Decorators to help fill the need for jars, containers & packaging. Contract Fillers often blend, fill and assemble product packaging to fit their customers’ need. Some even [...]

Plastic Containers for All Natural & USDA Certified Organic Nuts & Berries - Plastic Jars & Packaging for Trail Mixes, Dried Fruits & Nuts

Nut Packaging & Plastic Containers for Nuts, Trail Mixes, Dried Fruits, Sweeter Treats & Salty Snacks Looking to package your organic snacks or dried fruits in FDA-approved plastic containers? Nuts & dried fruits need reliable packaging to retain the freshness of the product & to stay sealed for maximum protection. Nut packaging comes in different shapes & sizes from plastic containers, plastic [...]

Plastic Jars and Caps - Selling Online - The Online Landscape - Alibaba vs. Ebay vs. Amazon vs. Etsy vs. Google Shopping

How do you sell your products online? Parkway Plastics' Plastic Jars and Caps online - Selling in a Digital Age through a variety of Marketing Channels While brick and mortar stores may be important in some industries, in packaging brick and mortar stores are quickly becoming a thing of the past. With the advent of the [...]

Dish Washer Safe, BPA Free, Plastic Shaker Bottle and Drink Supplement Bottles

Types of Protein Powders for Shaker Bottle - Protein Supplements vs Protein Powder Protein, Protein, Protein! Ahh protein: one of the 9 essential amino acids. Some come in powder form others in pills. According to WebMD, casein protein, whey protein and soy protein are among the popular ones used by avid gym goers. Casein protein and Whey [...]

Plastic Packaging for Sugaring and Sugar Warmers

As a manufacturer of hair removal and skin epilation products, we understand that you are looking for a cost-effective way to package your body sugaring products, exfoliants and depilatories. As a industry leading plastic jar manufacturer, we understand that your needs don't just stop there. You also want something that is of a premium quality, that [...]

Plastic Jars for Food Storage

Whether you are a Green Chef or wear a Blue Apron, carry a Sun Basket or are simply cooking out of Terra's Kitchen, we are all looking for new and easy ways to prep, store, Plate and portion our food. Not to mention keep our food as Fresh as possible for as long as possible! I [...]

Are you searching for BPA free FDA approved jars?

Look no further! Parkway Plastics has the BPA free FDA Approved jars you need. Parkway Plastics has been in the container manufacturing business for over 65 years. As a stock and custom plastic manufacturer, we use only BPA free FDA approved resins, colorants and materials because we care about you, your families, your customers and [...]

Jars and Caps for Medical Devices - How do I know my Jars can handle the Sterile Solution?

Searching for nice looking plastic jars for transcatheter mitral valves? When you need a plastic jar that enables you to store medical devices in a sterile solution, things can become a little more complicated. Medical device jars often need to be stored in a sterile solution. Finding a jar that will be compatible with the solution can [...]

Recent Posts

- » Buy Custom Plastic Jars Direct from Manufacturer - Parkway Plastics

- » California Packaging Regulations and You! How does Parkway stack up? Parkway Plastics Meets CA Rigid Plastic Packaging Container Laws!

- » Blow Molding Explained - How PET Jars and Containers are Manufactured!

- » How Reusable Packaging Can Help Improve Your Brand Image & Costs | Safe Plastic Jars for Reuse | Optimize Your Supply Chain with Reusable Plastic Jars and Packaging |

- » Parkway Now Offers Child Resistant Closures | CRC |