Loading... Please wait...

Loading... Please wait...Labeling Terms & Definitions: P-S

Posted by Kirstin Kelly on 06-27-2018

P

PADDING

Binding sheets of paper together by applying flexible glue or adhesive to one edge of the stack.

PANTONE MATCHING SYSTEM (PMS)

An international system of matching color for printing, designating unique colors by standard Pantone Matching System® (PMS) numbers. Pantone is known worldwide as the standard language for color communication from designer to manufacturer to retailer to customer. See our Pantone color chart for reference.

PASS

One trip for the material through a production piece of equipment. Certain constructions require additional passes to complete the production.

PATTERN ADHESIVE

See pattern coated.

PATTERN COATED

The width and spacing arrangement of strips of adhesive laid down parallel to machine direction and across the width of pressure sensitive label stock during its manufacture. Also refers to adhesive coating applied in a pattern which is not related to web direction. Pattern adhesives are used when dry lift areas are needed on a label and when different grades of adhesive on the same label are required.

PATTERN VARNISH

Spot varnish applied to the printed surface in a desired pattern.

PDF

Portable Document Format (PDF) is the standard for digital file transfer, where the information about all elements on the page; format, text, font, graphics etc, is delivered with the page. It is standard practice to provide a PDF of the label artwork with any request for quote.

PEARLESCENT PIGMENTS

A class of pigments consisting of particles that are essentially transparent crystals of a high refractive index. The optical effect is one of partial reflection from the two sides of each flake. When reflections from parallel plates reinforce each other, the result is a silver luster. Effects possible range from brilliant highlighting to moderate enhancement of the normal surface gloss.

PEEL ADHESION

Peel adhesion is the force required to remove a pressure sensitive label from a standard test panel at a specified angle and speed after the label has been applied to the test panel under specified conditions for a specific time period.

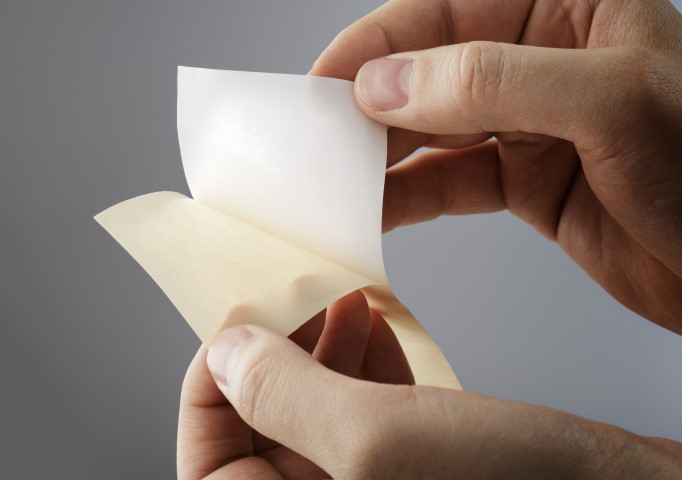

PEELBACK

A method of separating a bond of two flexible materials or a flexible and a rigid material that have been bonded with an adhesive. The flexible material is pulled from the mating surface at a 90 or 180 degree angle to the plane in which it is adhered. The stress is concentrated only along the adhesive line of immediate separation.

PEELER PLATE

A sharp-edged, flat piece of metal around which the backing or carrier material is threaded. The prime function being a mechanical device which causes a pressure sensitive label to be dispensed from the backing material.

PENETRATION

Change of appearance of the face material due to movement of one or more components from the adhesive or the labeled surface. Also called bleed through and migration.

PERFORATION

A line or row of cuts or tiny holes that enable a label or its liner to be folded, torn off or separated easily. Perforation may be horizontal or vertical, with standard or microperforations. Perforations can also allow labels to be segmented as needed by an application.

PERMANENCY

A measure of an adhesive’s ultimate holding power or bond strength. A permanent adhesive will develop a bond that makes label removal difficult or impossible without distorting or tearing the face stock or the surface the adhesive has bonded to.

PERMANENT ADHESIVE

An adhesive with relatively high ultimate adhesion to a wide variety of surfaces.

PERMEABILITY

The property of a material that allows or resists a substance to pass or flow through it.

PHARMACEUTICAL LABEL

There are a wide range of applications and solutions required for pharmaceutical labels. Some applications may require the inks to be autoclaved or sterilized, while others may need to be stored in a freezer. The label will often need secondary information printed with a thermal transfer printer.

PHOSPHORESCENT FACE

A face material coated with a phosphorescent ink that emits light in a visible spectrum.

PHOTOINITIATOR

In ultraviolet-curing systems, the chemical which, when exposed to UV light, breaks certain chemical bonds in the system to start the chain reactions which cause polymer formation. This chemical is commonly referred to as a catalyst.

PIGGYBACK LABELS

Pressure-sensitive label constructions that have two release coated liners, two layers of adhesive and a face material which enables the label to be applied, complete with the backing, for further or future application.

PIGMENT

The particles or substance that gives printing inks, dyes or paints their color.

PIN FEED

See feed slots.

PINHOLING

Refers to the failure of a printed ink to form a complete film. This condition will become visible by the appearance of small holes in the solid print area.

PLASTICIZER

A substance added to materials to impart softness, flexibility, workability, elongation and dispensability.

PLASTICIZER MIGRATION

The migration of liquid plasticizers from some plastics into an adhesive and/or face material. It often causes excessive softening or degrading of adhesives.

PLASTICIZER RESISTANCE

Plasticizers can migrate into adhesives and/or inks and cause a breakdown, resulting in loss of adhesion to the substrate. If the adhesive or ink is formulated to resist the plasticizer, the breakdown may not occur.

PLATE

The image carrier in letterpress and flexographic printing. Flexographic printing plates are made of a flexible polymer and wrap around a print cylinder for printing. Each color used on a label requires its own printing plate and ink station.

PLIABILITY

A property of face stock materials, measured under specified conditions, which indicates how readily they will conform to curved surfaces such as bottles, vials, or syringes. There are label materials specifically made where pliability is a requirement.

PLY

Each layer in a multi-layered structure.

PMS

Pantone Matching System® (PMS) is an international system of matching color for printing, designating unique colors by standard PMS numbers. Pantone is known worldwide as the standard language for color communication from designer to manufacturer to retailer to customer. See our Pantone color chart for reference.

POINT

Printer’s unit of measurement to designate type size. There are 12 points to a pica; approximately 72 points to an inch. Also, a term used for an expression of thickness of a sheet of material in one-thousands of an inch increments, I.e. 7 point = .007″ thick.

POLYCARBONATE

A thermoplastic polymer with excellent toughness characteristics. A composition of several layers is fused at high temperature.

POLYESTER

Made of polyetherylene terephthalate (PET), it is a high-performing film with excellent resistance to moisture, solvents, and oils. It provides excellent strength, clarity, and dimensional stability.

POLYESTER LINER

A polyester film that is silicone release coated. It provides an excellent die cutting surface and is often used for high speed automatic label applications or for overlaminating films to provide a smooth, glass-like surface of adhesive.

POLYESTER METALIZED FILM

A clear polyester film, vacuum metalized on one side to provide a metallic look.

POLYESTER OVERLAMINATION

A clear matte or glossy polyester film coated with clear acrylic adhesive.

POLYETHYLENE

A tough, stretch plastic film with very good low temperature characteristics. Also used a great deal for producing semi-rigid recyclable bottles.

POLYMER

A compound formed by the reaction of simple molecules called monomers, having functional groups that permit their combination to proceed to high molecular weights under suitable conditions. A long-chain molecular structure.

POLYMERIZATION

A chemical reaction initiated by a catalyst, heat or light, in which monomers and/or oligomers combine to form a polymer.

POLYPROPYLENE

Similar to polyethylene but stronger and having a higher temperature resistance. Various thermoplastics are polymers of propylene with excellent clarity. It is also used in various thicknesses in the printing of labels as well as backing or liner materials.

POLYSTYRENE

A thermoplastic produced by the polymerization of styrene. The electrical insulating properties are outstanding and the material is relatively unaffected by moisture.

POLYVINYL

Refers to a group of resins formed by polymerizing various vinyl monomers.

POLYVINYLIDENE CHLORIDE

A usually very thin transparent film with excellent resistance to acids, water and organic solvents.

POROSITY

The property of paper that governs the degree of permeability, I.e., the passage of a substance through it.

POST CURE

The continuation of a polymerization (curing) process within a UV ink or coating, after exposure to UV radiation has been terminated.

PREPRESS

The activities involved in setting up and preparing label artwork for printing.

PRESS VARNISH

A clear varnish applied in-line on a press. It can be overall or printed in pattern from a plate to allow for dry laps and other uncoated areas.

PRESS, WEB

Press which prints substrates supplied on rolls.

PRESSURE SENSITIVE ADHESIVE

Unlike other types of adhesives, they are able to form a bond at any time, permanently tacky and capable of bonding to almost any surface. No activation by water, solvent or heat is required to exert a strong adhesive bond on materials as diverse as paper, plastic, glass, wood, cement and metals.

PRESSURE SENSITIVE LABEL STOCK

The combination of face material, pressure-sensitive adhesive and release liner from which pressure sensitive labels are manufactured.

PRESSURE SENSITIVE LAMINATE

See pressure sensitive label stock.

PRESSURE SENSITIVE TAPE

A combination of a pressure sensitive adhesive with a carrier. Tapes are either self-wound or utilize release liners or films.

PRIMARY LABEL

A label that acts as the main identification of a product. Often designed to attract attention and contains information to appeal to a buyer and is usually applied at the time of its manufacture.

PRIME COAT

Base coat applied first to enhance subsequent printing.

PRIME LABEL

A label used to identify and display a product, I.e. a major product panel.

PRIMER

Surface coating applied between face stock and adhesive to improve bond performance and/or prevent bleed. See barrier coat.

PRINTABILITY

The ability of a material to accept and hold a printed legend, and especially to resist offset of the printing when rewound into a roll after printing. Also, a collective term used to describe the properties required of all components in the printing process.

PROCESS PRINTING

The four process color inks; cyan, magenta, yellow and black (CMYK), which are used in the printing of four color halftone labels.

PROTECTIVE COATING

Coating that protects the print and face material of a pressure sensitive label from abrasion, chemicals, and moisture. Also known as overcoat and overprint coating.

PSI

Pounds per square inch.

PULL ROLL

See nip.

PULL TAB

The area on a face stock that facilitates easy removal of the label, usually a cut area on a sheeted label. Also called a peel tab or tear tab.

PUNCHED OUT LABELS

Anvil cut or sheeted labels. Also referred to as metal-to-metal cutting due to the die cutting edge coming in contact with the anvil.

PVC

Vinyl; polyvinyl chloride.

Q

QUALITY MANAGEMENT

The ability to satisfy, or exceed, the needs and expectations of customers. Printing is a manufacturing process that uses variable components such as paper, inks, plates and films completed by machinery that will eventually show signs of wear, or can be set up differently by the same or different operators. All of these variable elements need to be quality managed and controlled when possible. ISO 9001:2008 has become the standard in the printing industry by which key users, brand owners and buyers assess whether the system and procedures are in place to manage and control quality.

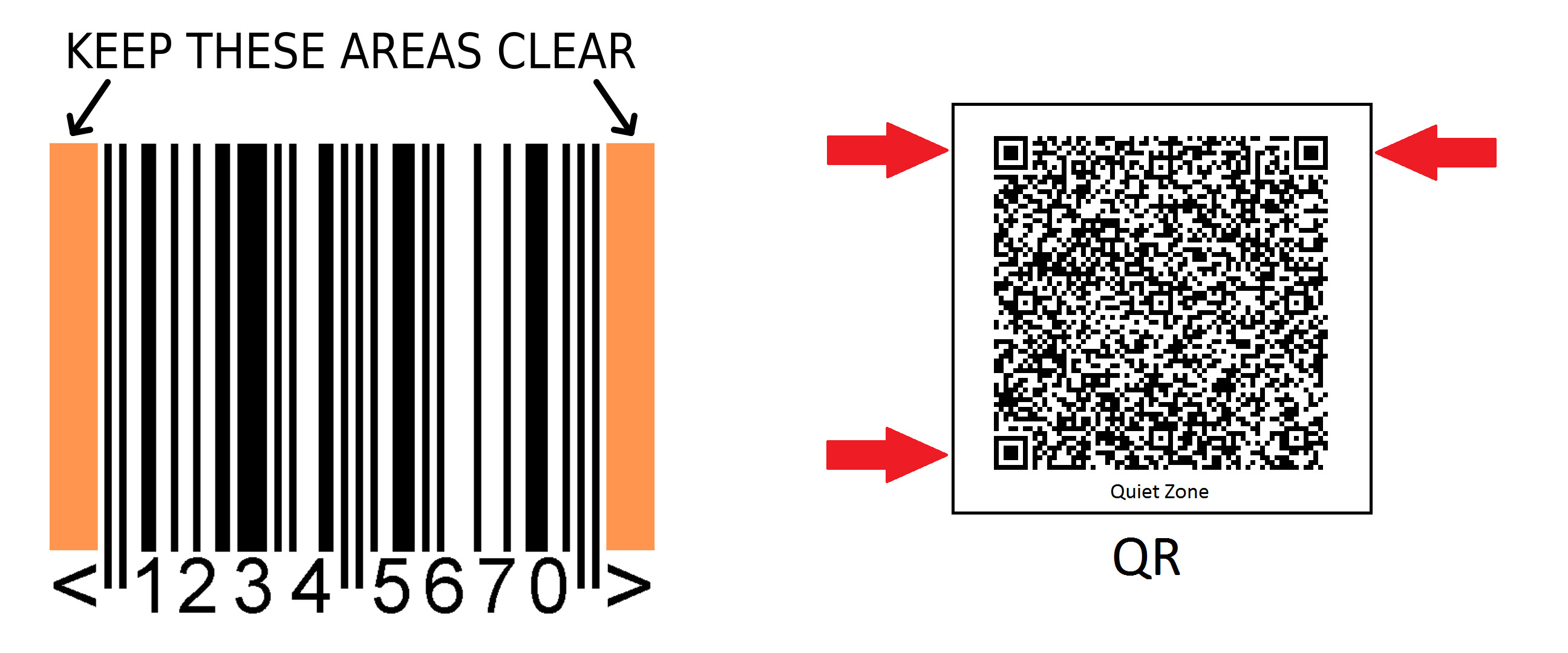

QUIET AREA

See clear area.

QUIET ZONE

The light margin or clear area that surrounds a bar code symbol if it is to be read successfully.

R

READ AREA

A term used to refer to the scan path or scan area.

REAM

Five hundred sheets of paper.

REAM WEIGHT

The amount which one ream of paper weighs.

RECYCLABLE

Materials that are able to be reprocessed and used again.

REEL

A finished roll of labels.

REFLECTANCE

The amount of light returned from an illuminated surface.

REGISTER

A term in pressure sensitive label production that describes exact placement of successively printed images and/or die-cut pressure sensitive labels.

REGISTER MARKS

Symbols attached to original copy for registering two or more colors when printing.

REGISTER

The corresponding placement of one color to the next, as well as the printing placement as it relates to die-cutting, scoring and perfing.

RELATIVE HUMIDITY

The amount of water vapor present in the atmosphere, expressed as a percent of maximum that could be present at the same room temperature.

RELEASE AGENT

Materials used to facilitate the removal of molded items from their molds. These agents can cause serious problems in adhesion when applying labels to the molded products.

RELEASE COAT

The release liner treatment material that allows pressure sensitive labels to release from the release liner. They are usually made of silicone.

RELEASE COAT TRANSFER

The transfer of release coat from the release liner to the pressure sensitive adhesive during release.

RELEASE LINER

The component of the pressure sensitive label stock which functions as a carrier for the pressure sensitive label. Prior to application, it protects the adhesive, and readily separates from the label immediately before the label is applied to product.

RELEASE

The force required to free or separate a pressure sensitive label from its release liner, using a specific measuring device.

REMOVABILITY

A relative term applied to pressure sensitive labels to describe the force or condition under which they can be removed from a substrate. A removable label would be one in which no damage or staining occurs to the substrate or the face material on removal.

REMOVABLE ADHESIVE

A pressure sensitive adhesive characterized by low ultimate adhesion and clean removability from a wide variety of surfaces.

REPEAT

The printing length of a plate cylinder, determined by one revolution of the plate cylinder gear.

REPOSITIONABLE

The ability of a pressure sensitive label to be bonded to a surface, removed and repositioned. This can only be done for a limited period of time (e.g., 20 minutes). Beyond that time, the bond may begin to become permanent if a removable adhesive wasnt used.

RESIDUE

The adhesive left on substrate when a label is removed.

RESOLUTION

The crispness or sharpness of an image or typeface, either on a monitor or an output device.

REVERSE PRINTING

Printing on the underside of a transparent film. Also a design in which the copy is ‘dropped-out’ and the background is printed making the copy appear in the color of the background.

REWIND

The take-up spindle or mandrel on a press. Also, the act of winding a roll of material through a machine to effect the opposite unwind.

REWINDING & INSPECTION

The operation of winding the material from the press roll onto a core (or coreless) to produce rolls of the desired width, diameter and tension. Out-of-spec labels can be removed during this operation.

RIGHT READING

An image whose parts are spatially oriented to each other on the original, in contrast to the way they would appear reflected in a mirror.

ROCKWELL HARDNESS

A method of determining the surface hardness of a substance. Also called degree of hardness.

ROLL LABEL

Pressure-sensitive labels that are produced in a continuous roll form.

ROLL-TO-ROLL

A method of running materials through a printing machine. A roll of material is fed into a printing unit, printed and then rewound into a roll as it exits the machine.

ROLL-TO-SHEET

A method of running material through a printing machine. A roll of material is fed into a printing unit then sheeted as it exits the printing machine.

ROTARY PRESS

A press that in normal use features a roll-to-roll operation.

ROTARY PRINTING

Accomplished by means of a cylindrical impression cylinder and printing plate.

RUB RESISTANCE

Testing of print, label and packaging inks for rub resistance can be carried out using a number of rub resistance or rub tests.

RUB TEST

Test performed to determine the durability and abrasion resistance of the printed surface of a label.

RUBBER BASE ADHESIVE

Pressure-sensitive adhesive based on natural or synthetic rubber. Can be coated as a solvent, hot melt or emulsion system.

RUNNING REGISTER

That control on a flexographic press which accurately positions, while in the run mode, the printing of each color station in the direction of the web travel. Also called circumferential register or longitudinal register.

S

SANDWICH CONSTRUCTION

Panels composed of a lightweight core material to which two relatively thin, dense, high strength faces or skins are adhered.

SATURATION

The addition of various materials such as latex or rubber to a face material so as to improve its various physical properties. Also called impregnation.

SCAN

The search for a symbol which is to be optically recognized. It searches for marks to be recognized by the recognition unit of the optical scanner.

SCORE

To make an impression or a partial cut in a material for the purpose of bending, creasing, folding, or tearing.

SCORE CUT

See score.

SCREEN PRINTING

A method of printing in which the ink is forced through a design on a taut screen and onto the object to be printed. This process results in a heavy ink deposit that provides excellent outdoor durability.

SCUFF

The action of rubbing against a surface with applied pressure. Also, the damage which has taken place through rubbing.

SEALER

A coating designed to prevent the passage of a substance through a substrate.

SECONDARY LABELS

Where primary and secondary labels are adhered to a product, the secondary label is usually smaller and positioned not to detract from the primary brand label. They are used to carry information such as health or safety requirements, nutritional details, instructions for use, EAN code, warnings, manufacturer or supplier information. Secondary labels are also used for tracking purposes. Also known as information or variable information labels.

SELF-ADHESIVE LABEL

See pressure sensitive label stock.

SELF-ADHESIVE PRODUCTS

Converted pressure sensitive labels and products usually carried by a release liner.

SELF-CHECKING

A bar code or symbol using a checking algorithm which can be applied to each character to guard against undetected errors. Non self-checked codes may employ a check digit or other redundancy in addition to the data message.

SELF-EXTINGUISHING

A somewhat loosely used term describing the ability of a material to cease burning once the source of flame has been removed.

SELF-WOUND

A roll of material with a single liner, which is coated on both sides with a release coating and a carrier having a pressure sensitive adhesive on both sides. Also, a material that has pressure sensitive adhesive applied to one side and then rolled up on itself without a release liner).

SEMI-AUTOMATIC

A labeling machine in which only part of the operation is controlled by the direct action of a human. The automatic part of the operation is controlled by the machine.

SEMI-GLOSS PAPER

Coated, one-sided litho.

SEPARATOR

See pattern coated.

SERIAL CODE

A bar code symbol typically used with a fixed beam scanner where the scanning action is caused by the motion of the symbol past the scanning head. The bits of the symbol are evaluated one at a time as the symbol passes.

SERVICE TEMPERATURE

The temperature range that a P.S. label will withstand after a 24-hour residence time on the substrate. The range is expressed in degrees Fahrenheit or Celsius. Also called exposure temperature.

SET

The point during the bonding process when the adhesive has reached such structural proportions that it prevents the movement of the substrate’s surface.

SETUPS

See makeready.

SHEAR CUT

A cut of a continuous web of stock using an action similar to the action of scissors.

SHEAR RATE

Time required for breakdown of the shear strength.

SHEAR STRENGTH

The relative resistance of an adhesive coated film or paper to a stress applied in such a manner that the adhering surfaces slide in a plane parallel to their plane of contact; the internal or cohesive strength of the adhesive.

SHEAR STRESS

Where normal stress is perpendicular to the designed plane, shear stress is parallel to the plane.

SHEAR TEST

A method of separating adhesive bonded materials by forcing the interfaces to slide over each other. The force exerted is distributed over the entire bonded area at the same time. Strengths are recorded in pounds per square inch, or in minutes or hours to failure.

SHEAR

The relative movement of adjacent layers in a liquid or plastic during flow. See cohesive strength.

SHEET-FED

Designates a printing press to which paper is fed in sheets rather than rolls.

SHEET-FORM

Pressure sensitive label stock packaged in sheets and designed for used on a sheet feed press.

SHEETING

The process whereby rolls of label stock or tag stock are converted into sheets of finished product by cutting them to the desired length in the sheeting stations on a rotary press. Once cut, the sheets enter the stacker accessory.

SHELF LIFE

The period of time during which a product can be stored under specific conditions and still remain suitable for use. Supplied material has a shelf life of one year. Also known as storage life.

SHELLAC

An alcohol-soluble natural resin widely used in flexographic inks.

SHRINK WRAPPING

A method of packaging where labels are overwrapped with a shrink film and then passed through a heat tunnel to shrink the film tightly against the labels.

SHRINKAGE

Reduction in any dimension.

SILICONE

A polymer of organo-siloxane used as an ink additive to aid ink flow out. Also used for pressure sensitive adhesives capable of withstanding extreme temperatures. A polymeric material with exceptionally high repellency properties towards adhesives used extensively in the coating of release liners.

SILICONE ADHESIVE

Adhesive compounds of this base have remarkable stability through a wide temperature range. Chief limitations for use are the high temperature cure and sensitivity to aliphatic and aromatic fuels; pressure sensitive adhesive which permits bonding to difficult surfaces; outstanding high temperature and low temperature performance; high resistance to oxidation; ozone and corona radiation and good dielectric properties.

SILICONE COATING

A unique polymer system which is the standard release coating for pressure sensitive constructions.

SILICONE STAIN TEST

A water-based stain used to test silicone coating coverage and continuity on die cut paper release liners.

SINGLE-FACED

Where adhesive is applied to one side of a carrier, as in self-wound laminating films and tapes.

SIX SIGMA

A management methodology that enables businesses to achieve a goal of increasing profits, improving product quality, and enhancing employee morale by eliminating waste, decreasing process variation, and identifying and reducing defects in manufacturing. Six Sigma refers to the mathematical term of six standard deviations from the mean, and a process that is capable of six sigma would produce no more than 3.4 defects per 1 million pieces.

SKIPPING

Missing print, tints or coatings on a substrate due to dry-in of ink or coatings in the cells of the anilox roll.

SKIPS

Areas wherein the adhesive or the release coating are missing from the lamination.

SLIP ADDITIVE

Additive to inks or varnishes to effect improved slip or lubricating qualities.

SLIT

To cut rolls of stock to specified widths. Either rotary or stationary knives or blades are used with mechanical unwinding and rewinding devices.

SLITTER

A machine used to cut roll stock in the long direction. Three types are used: 1) razor blade slitter, 2) shear slitter, and 3) score slitter.

SLOT

A cut made in a material of a specific size and location. May have the face material removed when used to feed through imprinters.

SMUDGE RESISTANCE

Resistance of a printed paper surface to ink blurring or smearing and thus related to the absorption of the paper.

SMUDGE RESISTANCE

The resistance of a printed surface to smearing.

SOLIDS CONTENT

The percentage weight of non-volatile components in an ink, coating or adhesive.

SOLVENT

A liquid substance capable of thinning or reducing the viscosity of ink, coating or adhesives. Water is a solvent, but the term usually refers to organic liquids.

SOLVENT ADHESIVE

Adhesive components that are dissolved in a variety of organic solvents for coating. Rubber or acrylic based systems can be coated this way.

SOLVENT RESISTANCE

The resistance of a pressure sensitive label to the action of specific organic liquids. May apply to either adhesive or printing.

SOLVENT-FREE

The absence of any solvent in an ink, coating or adhesive.

SOLVENTLESS SILICONE

A silicone release coating applied without the use of any organic solvent or water. Also known as 100 percent solids silicone.

SPACE

The lighter element of a bar code formed by the background between bars.

SPECIFIC ADHESION

The force required to remove a pressure sensitive adhesive from a specific product under precise conditions. Also, the relative tendency of adhesives to form bonds on specific surfaces. Some may be permanent on one surface and removable from another.

SPECIFIC GRAVITY

The ratio of the weight of a specimen to the weight of an equal volume of water.

SPLICE

A method of joining webs to produce an operational continuous web.

SPLIT BACK

Slits in the release liner to facilitate its removal by hand.

SPLIT FACE

Slits in face or pressure-sensitive product usually for facilitating removal from the release coated backing.

SPLIT LINER

See split back.

SPOT LABEL

Label that does not extend completely around can or bottle. Usually confined to less than half the circumference.

SPOT VARNISH

See pattern varnish.

SPREAD

The enlargement of a printed image from the printing plate to the printed image. Also, a photospread to achieve required ink bleeds or traps.

SPREADS AND CHOKES

See chokes and spreads.

SPUNBONDED OLEFIN

A synthetic plastic material formed by the random distribution of very fine continuous fibers which are self-bonded by heat and pressure.

SQUEEZE-OUT

The flow of excess adhesive or coating when pressure is applied.

STABILIZE

To increase the steadiness of a film, keep it from changing or fluctuating. Usually vinyl films are stabilized by laminating polyester to one or both sides of the vinyl.

STABILIZED KRAFT

Term used to describe paper that is treated to provide moisture resistance and dimensional stability.

STABILIZER

An ingredient used in the formulation of some plastics, especially elastomers, to assist in maintaining the physical and chemical properties of the compounded materials at their initial values throughout the processing and service life of the material.

STACKER

An accessory device on the take-off end of a press that automatically stacks sheeted labels.

STAIN RESISTANCE

The ability of a label to be applied to a surface without discoloring that surface. Also, the ability of a printed label to resist staining due to exposure to the product being labeled.

STAINING

A discoloration of a surface caused by adhesive residue.

START/STOP CHARACTER

A bar code character that provides the scanner with start or stop reading instructions as well as code orientation. The start character is usually to the left and the stop character to the right of a picket-fence oriented code.

STATIC CLING

An induced property of a film which enables it to grab onto a smooth clean surface without using a pressure-sensitive adhesive. Static cling is a phrase applied to both mechanical grabbing and grabbing by electrical static.

STATIC

Electrical charges generated in handling materials which cause materials to cling together. Can jump to humans or equipment causing shock or fire if solvents are present. Often causes films to cling together or to other insulating surfaces.

STATIC ELECTRICITY

A built-up electrical charge on the surface of a substrate or other surface. It is usually induced by friction and low atmospheric humidity conditions.

STEP AND REPEAT

The act of creating multiple complete images on film or an electronic art file in preparation for plate making.

STICKYBACK

Double faced adhesive coated material used for mounting printing plates to the plate cylinder.

STIFFNESS

The measure or degree of resistance to bending stress of a material.

STOCK

Paper or other material to be converted.

STORAGE STABILITY

The ability of a material to be stored under normal conditions of temperature and humidity without change in its properties.

STRIKE-THROUGH

The penetration of the adhesive or ink through the substrate.

STRINGINESS

A condition of the adhesive in which it feels very soft and mushy. On close examination, relatively long ‘strings’ of adhesive can be pulled out.

STRIP COATED

See pattern coated.

STRIPPER-PLATE

See peeler plate.

STRIPPING

The removal of the excess face material and adhesive (the matrix waste) from around the die-cut label shape by taking it around a roller, or over a metal bar, prior to being wound up on its own roll for disposal or recycling. Also called waste stripping or weeding.

STYRENE

A liquid unsaturated hydrocarbon (C8H8). See polystyrene.

SUBSTRATE

The surface to which a label is applied. Converters also refer to the face stock being printed as the substrate.

SUBSURFACE PRINTING

Printing the underside of a transparent film. Ultimately the ink will be sandwiched between the film that was printed and the adhesive holding it to the surface to which it is applied.

SUNLIGHT RESISTANCE

The ability of a material to resist the deteriorating effects of sunlight especially those wavelengths in the ultraviolet and the infrared ends of the spectrum.

SUNLIGHT RESISTANT ADHESIVE

An adhesive which contains an inhibitor to resist destruction by ultraviolet rays.

SURFACE PREPARATION

The physical and chemical methods used to prepare a surface for further processing.

SURFACE RESISTIVITY

The electrical resistance of a material between the two opposite points of a unit of its surface.

SURFACE TENSION

The property, due to molecular forces, by which all liquids through contraction of the surface, tend to bring the contained volume into a form having the least area. If an ink is to be compatible with a substrate, the surface tension of the ink must approximate that of the substrate.

SURFACTANTS

A coined word used in industry to include all surface active agents.

SYMBOL LENGTH

The length of a symbol measured from the beginning of the quiet area adjacent to the start character to the end of the quiet area adjacent to the stop character.

SYNTHETIC RESIN

Resins prepared by chemical means.

SYNTHETIC RUBBER

Elastomer manufactured by a chemical process as distinguished from natural rubber obtained from trees.

SYNTHETICS

Those materials developed and manufactured through chemistry, which tend to replace natural materials.

Ref:

https://coastlabel.com/glossary/#1464296320016-33d...

https://coastlabel.com/glossary/#1464296409189-432...

https://coastlabel.com/glossary/#1464296924506-46c...

1/4 oz 33 mm Labels- 10 ml jar label template , 7 g plastic jar labeling template

1/2 oz 33 mm Labels - 15 ml jar label template , 14 g plastic jar labeling template

7/8 oz 33 mm Labels - 25 ml jar label template , 24 g plastic jar labeling template

1 oz 38 mm Labels- 30 ml jar label template , 28 g plastic jar labeling template

1 1/2 oz 38 mm Labels - 45 ml jar label template , 42.5 g plastic jar labeling template

1/2 oz 43 mm Labels- 15 ml jar label template , 14 g plastic jar labeling template

1 oz 43 mm Labels - 30 ml jar label template , 28 g plastic jar labeling template

2 oz 43 mm Labels - 60 ml jar label template , 57 g plastic jar labeling template

2 oz 48 mm Labels - 60 ml jar label template , 57 g plastic jar labeling template

1/2 oz 53 mm Labels- 15 ml jar label template , 14 g plastic jar labeling template

2 oz 53 mm Labels- 60 ml jar label template , 57 g plastic jar labeling template

3 oz 53 mm Labels- 90 ml jar label template , 85 g plastic jar labeling template

3 oz 58 mm Labels- 90 ml jar label template , 85 g plastic jar labeling template

4 oz 58 mm Labels- 120 ml jar label template , 113 g plastic jar labeling template

6 oz 63 mm Labels- 180 ml jar label template , 170 g plastic jar labeling template

8 oz 63 mm Labels - 240 ml jar label template , 226 g plastic jar labeling template

10 oz 63 mm Labels- 295 ml jar label template , 283 g plastic jar labeling template

12 oz 63 mm Labels - 355 ml jar label template , 340 g plastic jar labeling template

1 oz 70 mm Labels- 30 ml jar label template , 28 g plastic jar labeling template

2 oz 70 mm Labels- 60 ml jar label template , 57 g plastic jar labeling template

3 oz 70 mm Labels- 90 ml jar label template , 85 g plastic jar labeling template

4 oz 70 mm Labels- 120 ml jar label template , 113 g plastic jar labeling template

6 oz 70 mm Labels- 180 ml jar label template , 170 g plastic jar labeling template

8 oz 70 mm Labels - 240 ml jar label template , 226 g plastic jar labeling template

3 oz 83 mm Labels - 90 ml jar label template , 85 g plastic jar labeling template

4 oz 83 mm Labels- 120 ml jar label template , 113 g plastic jar labeling template

6 oz 83 mm Labels- 180 ml jar label template , 170 g plastic jar labeling template

4 oz 89 mm Labels- 120 ml jar label template , 113 g plastic jar labeling template

6 oz 89 mm Labels- 180 ml jar label template , 170 g plastic jar labeling template

8 oz 89 mm Labels- 240 ml jar label template , 226 g plastic jar labeling template

12 oz 89 mm Labels- 355 ml jar label template , 340 g plastic jar labeling template

16 oz 89 mm Labels- 475 ml jar label template , 448 g plastic jar labeling template

20 oz 89 mm Labels - 590 ml jar label template , 566 g plastic jar labeling template

6 oz 100 mm Labels- 180 ml jar label template , 170 g plastic jar labeling template

8 oz 100 mm Labels- 240 ml jar label template , 226 g plastic jar labeling template

10 oz 100 mm Labels- 295 ml jar label template , 283 g plastic jar labeling template

16 oz 100 mm Labels - 475 ml jar label template , 448 g plastic jar labeling template

20 oz 100 mm Labels - 590 ml jar label template , 566 g plastic jar labeling template

26 oz 100 mm Labels - 768 ml jar label template , 737 g plastic jar labeling template

16 oz 120 mm Labels- 475 ml jar label template , 448 g plastic jar labeling template

24 oz 120 mm Labels- 710 ml jar label template , 680 g plastic jar labeling template

32 oz 120 mm Labels - 950 ml jar label template , 907 g plastic jar labeling template

40 oz 120 mm Labels - 1185 ml jar label template , 1134 g plastic jar labeling template

Recent Posts

- » Unlocking the Potential of Plastic Jars: Your Ultimate Storage Solution

- » The Ultimate Guide to Choosing the Perfect Plastic Jars for Your Needs

- » Parkway Plastics Wide Mouth, Round Body: Shop the Perfect Plastic Jar Here!

- » The Versatility and Innovation of Plastic Jars and Bottles

- » High-Quality Plastic Jars and Bottles for Every Need